|

OPTI-KNIFE GRINDING RECOMMENDATIONS

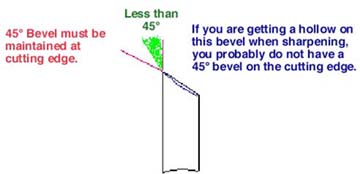

The Knife must project out of the head body a sufficient amount to keep the grinding wheel on the profile grinder from hitting the head body. On a 6?" diameter head with a 20 cutting angle, using a 5/16" corrugated knife, with a 45 knife bevel, the projection from the head body is approximately 3/8" of an inch. 45 bevel must be maintained on the Opti-Knife. (See illustration above). The proper grinding method would be to rough the pattern in with our WA462 or BA463 wheel on a Weinig Grinder(or comparable wheel for other grinders). These wheels are specially formulated to grind Opti-Knife; as well as, other tough grinding steels. You would then use our WA100 wheel to finish the profile in the knife. This insures a smooth finish on the steel to eliminate any lines from the 60 grit wheel. Customers that are jointing Opti-Knife may find that the use of a fine grit wheel is unnecessary, because the jointing stone provides a more than adequate finish. For best results when grinding Opti-Knives, use a RPM that is about 500 RPM higher than normal. For example, if you usually rough grind at 1200 RPM’s, speed it up to about 1700 RPM’s. If you finish grind at 2200 RPM’s, go up to 2700 RPM’s. When grinding these knives, a water coolant is used to keep the knife steel from heating up and turning blue. By using the same template when sharpening, the knife grinder can maintain the same pattern with a high degree of accuracy. Opti-Knives are very burn resistant at lower speeds and wheel wear is about average providing the wheel is kept dressed properly. The knife can then be joined with our 600 grit stone on high speed machines (6000 RPM Spindles) or our 400 grit stone on 3600 RPM machines. It is very important that the joint be no thicker than a hairline. Remember, the #1 rule in grinding knives is Do Not burn the steel. Once it becomes colored, you must grind down to rid the knife of the burn marks. Finish of material is directly related to the feed and speeds of the machine. For further assistance or recommendations for your specific application, call our customer service department (828) 628-4414. |

||

|

To

reach a friendly voice, call during our hours of operation:

|

||