What is a Milled To Pattern (MTP) Bit?

All WKW milled-To-Pattern Bits are precision machined for accuracy and finish. Made to your exact specifications, milled-to-pattern bits use AISI M-2 high-speed steel, carbide, or other tool steels and are heat-treated for maximum wear. Machined to exacting tolerances, each bit is projected on an optical comparator to ensure minute detail accuracy.

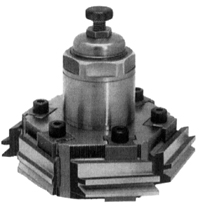

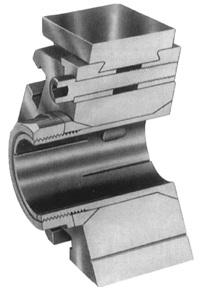

Milled-to-pattern bits can be designed to fit most standard makes of cutterheads. This means your pattern will provide constant, dependable production. Send us a drawing or sample of your pattern.

Milled-to-pattern bits are recommended where long runs or frequent runs of the same moulding or pattern are made. The term "milled-to-pattern" bits is used because of the way the bits were originally manufactured. However, with the coming of modern technology, we now do 90-95% of our milled-to-pattern bits on our Wire E.D.M. computer-controlled machines. Our engineers utilize CAD-CAM to develop the proper information for the computer program. If bits are reordered by the symbol stamped on the bits, the customer will receive the identical bit.

Types of MTP Bits:

| | |||

| No corrugations vice grip bits | Corrugations | Semi-clamp-type cope bits | Double dovetail |

| |||

| Single dovetail | Wood-type bits | Lug type bit | "L" type bits |

Wood patterns are cut with the bits and profiles are checked on our comparator against pattern drawings. All bits are balanced.

Milled-to-pattern bits are easy to maintain. When they become dull, it is a simple matter to face-sharpen them by taking off only a few thousands. (This is true of a proper maintenance schedule.)

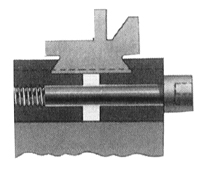

When face-sharpening, it is important to follow the same angle that is milled on the face. (If this angle is changed, the bit will not cut the correct pattern,) When bits are assembled in a head, they must be set to the head angle. When bits with corrugations are sharpened back 1/16th of an inch, they should be reset to the head angle. "L"-type bits must be ground to adjust for proper cutting angle.

The bevel that is milled on the face of the bit determines the cutting angle. Bits are designed to give the proper cutting angle when cutting a specific kind of wood. Bits will have more than one dovetail for wide patterns.

Bits are usually made from high-grade tool steels, including M-2, carbide-tipped and OPTI.

Common MTP Applications:

- Multiple dowel profiles

- Louvre slats

- Very long runs

- Critical fitting parts

- Rail and Stile

Call 1-800-Tooling for Pricing.

To reach a friendly voice, call during our hours of operation:

Monday through Friday, 9 a.m. to 6 p.m. EST

(Eastern Standard Time)

Wood Tech Enterprises

Our website: www.woodtechtooling.com

P.O. Box 2226

Fairview, NC 28730 USA

1-800-TOOLING (866-5464)

Phone: 828-628-4414

Fax: 828-628-4490

Shipping Address:

15 Khristy Scott Lane

Fairview, NC 28730 USA

Copyright © 1998-2011 Wood Tech Enterprises, Inc.

All Rights Reserved. Designated trademarks and brands

are the property of their respective owners.

Wood Tech is not responsible for typographical errors.

Prices are subject to change. All prices are in U.S. Dollars.