Click

here to go to![]() our Reference

Library of Industry Guidelines.

our Reference

Library of Industry Guidelines.

Click to go to the Main Jointer Stones page

Click

to go to

Other Jointer Stones

Click

to go

to Weinig Jointer Stones

JOINTER

STONES 101

JOINTER

STONES 101

Wood

Tech offers the largest selection of jointing stones in the world!

After many years of product testing, we have endorsed a select group of

products, including the well-known Atlantic products. These stones are

accepted world-wide as the "cream of the crop", and are made

of high-purity silicon carbide. The result is a longer stone life, superior

finish, and absence of impurities in the product.

Put simply: these stones provide the best possible choice for your

applications.

Two basic

types of jointer stones (Hard and Soft) are used in the woodworking industry.

In general, hard stones are used on older machines running at 3,600

RPM's. Detail to precisely forming the stone is critical, as the stone

can "reform" the profile on the knife if mis-made. Soft stones

- as used on more modern 6,000 and higher RPM machines, are more forgiving

and can be "chipped in" to properly fit the knife.

Click here to go to ![]() Jointer

Stones Recommendation Charts

Jointer

Stones Recommendation Charts

Jointer Stones are similar to grinding wheels in composition. Please refer

to

(![]() GRINDING

WHEEL # 101 for more detailed information)

GRINDING

WHEEL # 101 for more detailed information)

ABRASIVE MATERIALS:

- Silicon Carbide: ( Green) Cuts cooler and faster than Black Silicon Carbide.

- Silicon Carbide: (Black) Smoother finish, longer life.

- Aluminum oxide : (White, Pink, Orange) Cuts fast and cool, best for Straight Joints on Planers.

BONDS:

Vitrified:

- Easier to shape

- Cuts cooler

- Holds the profile better and longer than resin bond.

Resin:

- More difficult to shape

- Better finish joint

- More resistant to chip abrasion.

- Will remove more steel, but must be cleaned and refreshed periodically.

GRITS:

For

HSS Applications:

Hard stones:

- 60-120 White Straight Knife

- 80-400 grit Black Silicon carbide (Straight & Profile)

- 240-400 grit Green Silicon Carbide (Straight & Profile)

Soft stones

- 280-400 grit: Straight knife

- 500-600 grit Profiling

For Carbide Applications (See Jointing Carbide Knives for more information):

Hard Stones:

- 220 -240 grit Black Silicon Carbide (Profiling)

- 240 -400 grit Green Silicon Carbide ( Straight & Profiling)

Soft Stones

- 150-220 grit special blended Aluminum Oxide (Profiling)

Note: harder than the super soft stone, but not quite as hard as

the hard stones used for 3600 rpm on HSS.- 240 grit Black Silicon Carbide (Straight)

HELPFUL HINTS :

- Use a

dedicated grinding wheel to form the stone. DO NOT use the

same wheel to grind knives, as steel chips will be transferred back to

the jointer stone. This will produce "nicking" of your knives. - Finer

grits (higher numbers)produce better finishes because the

grains are finer. Coarse grits will remove more steel, and finish

results won't be as smooth. - The harder the stone, the more precise the shaping must be. Soft stones can be chipped-in with the actual cutterhead to assure exact counter profile.

- Soft stones aren't designed to remove nicks from knives.

- Wax impregnated

stones are more forgiving, and the lubricitity helps

prevent the stone from being over jointed. An added benfit is a reduced

dust level. - Always be familiar with MSDS for both the stone and the steel being used. Wear appropriate venilation equipment and have proper air transfer to avoid inhalation.

- IMPORTANT NOTE: As in any jointing stone forming process, use ONLY a wheel to form the stone that has not been used to grind ANY knives. Using a grinding wheel that has been in contact with knives will result in small metal particles being impregnated into the jointing stone. This foreign matter will adversely affect the stone performance by nicking the knives.

SHAPING INSTRUCTIONS

Note: Grinding accuracy is critical in determining proper jointing stone selection.

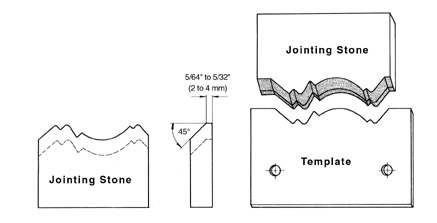

First, layout the stone using the pattern knife to be jointed. It is most important to maintain as accurate a mirror image fit as possible to the profile being jointed, as the jointing stone will in effect re-profile the knife if not properly formed. Now pre-shape the stone as accurate a fit as is possible.

Taper the stone on both sides at a 45° angle. This angle allows faster chipping-in of the stone. Insert the stone into the holder on the machine, and chip the stone in for exact fit. The use of only one knife in the chipping-in process results in a better fit. After the stone is chipped-in to fit, start the spindle and bring the stone into the knife at a slow to moderate speed. One technique is to bring the stone in and out in 1 second intervals, making minor adjustments at each interval. Another technique is to bring the stone in and hold it in slight contact with the knives. Depth control adjustments are made while contact is being made. This technique is tricky as extended time of contact can cause the stone to glaze.