| BAND SAWBLADES 101 |

Information courtesy of:  |

Click here to our Reference Library |

| Click here for info on product selection |

| Click here to go back to Lenox Band Saw Blades |

| |

| Lenox Blade Construction Terminology |

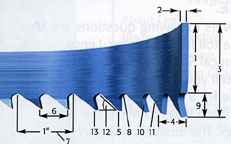

| 1 |

Blade Back

|

The body of the blade not including tooth portions. |

|

| 2. |

Thickness |

The thickness of the blade. |

| 3. |

Width |

The nominal dimension of a sawblade as measured from the tip of the tooth to the back of the band. |

| 4. |

Set |

The bending of the teeth to right or left to allow clearance of the back through the cut. |

| 5. |

Tooth |

The cutting portion of a saw blade. |

| 6. |

Tooth Pitch |

The distance from the tip of one tooth to the tip of the next tooth. |

| 7. |

T.P.I. |

The number of teeth per inch. |

| 8. |

Gullet |

The curved area at the base of the tooth. |

| 9. |

Gullet Depth |

The distance from the tooth tip to the bottom of the gullet. |

| 10. |

Tooth Face |

The surface of the tooth on which the chip is formed. |

|

| 11. |

Tooth Back |

The surface of the tooth opposite the tooth face. |

|

| 12. |

Tooth Rake Angle |

The angle of the tooth face measured with respect to a line perpendicular to the cutting direction of the saw. |

| 13. |

Tooth Face |

The cutting edge of the saw tooth. |

|

| |

| Lenox Bandsaw Tooth Set Options |

|

| Lenox Set |

|

| |

Five tooth or seven tooth sequence (right, left, right, left, straight), uniform set angle. |

| Raker Set |

|

| |

Three tooth sequence (left, right, straight), uniform set angle. |

| VARI-Raker Set |

|

| |

Multi-tooth sequence depending on tooth, varying set angle, 14/18 Vari-tooth has random wavy set. |

| Alternate Set |

|

| |

Every tooth set in an alternating sequence. |

| Wavy Set |

|

| |

Groups of teeth set to each side. Teeth have varying amounts of set in a controlled pattern |

|

| Lenox Bandsaw Tooth Type or Style |

| The most common tooth types are the regular tooth and the variable tooth. (Variable tooth is only available in the Bi-Metal). See Below: |

| |

|

|

|

| |

Regular Tooth - Straight faced tooth with deep gullets to rake out chips. This style is used for general metal cutting. |

|

|

| |

Hook Tooth - Widely spaced teeth and deep gullets with teeth that have a ten degree undercut face which helps to dig in and take a good cut while the gullets tend to curl the chips. This type is good for harder nonferrous alloys, harder woods and many plastic operations. Available in raker set only. |

|

|

| |

Skip Tooth - Very similar to the hook tooth but characterized by a straight 90 degree tooth and a sharp angle at the junction of the tooth and gullet. This type tends to break up the chips. This style is good for soft nonferrous metals that have a tendency to gum and clog the blade and it is also popular in wood cutting. Available in raker set only. |

|

|

| |

Variable Tooth - (Bi-Metal only) Also known as vari-tooth or broach tooth, this tooth has varying set angles and gullet depths. The variable tooth cutting edge reduces vibration while the back absorbs the impact of cutting in and out of holes, slots, and narrow webs. This is the best all-purpose blade for production work and for general shop cut-off and contouring. Use it for cutting off solids, bar stock and especially structurals. |

|

To reach a friendly voice, call during our hours of operation:

Monday through Friday, 9 a.m. to 6 p.m. EST

(Eastern Standard Time)

Wood Tech Enterprises

Our website: www.woodtechtooling.com

P.O. Box 2226

Fairview, NC 28730 USA

1-800-TOOLING (866-5464)

Phone: 828-628-4414

Fax: 828-628-4490

Shipping Address:

15 Khristy Scott Lane

Fairview, NC 28730 USA

Copyright © 1998-2008 Wood Tech Enterprises, Inc. All Rights Reserved. Designated trademarks and brands are the property of their respective owners. Wood Tech is not responsible for typographical errors. Prices are subject to change. All prices are in U.S. Dollars. |