|

No

grease output

|

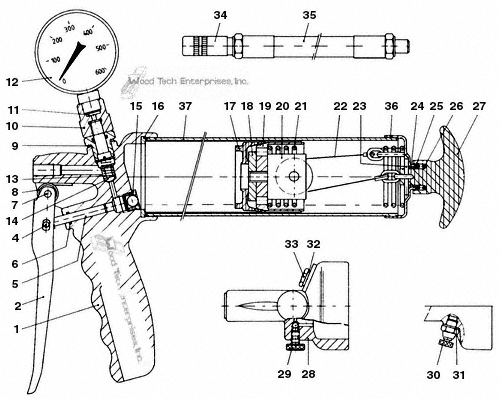

- a) Check if there is grease in cartridge. If handle item

27 can be pulled back without effort i.e. without resistance

from spring item 20 then there is still grease in cartridge.

If not, fit new cartridge.

|

- b) Check for trapped air. Open air release valve

item 30 and operate lever item 2 until air free grease is

release. Close valve.

|

|

No

pressure

|

- a) Check that pressure release screw is tight.

|

- b)Non-return valve item 15 may be dirty. Pull back

handle item 27 and lock chain into end cover item 36.

Unscrew barrel item 37 from head and clean valve item 15.

|

- NOTE: Do not use metal tools to clean ball valve

seating

|

|

Pressure

rises and falls immediately

|

- a) Valve plug item 14 may be dirty or faulty. To

clean or replace valve plug, unscrew barrel item 37 as previously

explained and remove rotary coupling item 10 from gun head.

Operate lever item 2 to eject valve plug item 14 and spring

item 13. Clean valve seating in head and clean or

replace plug item 14. Re-assemble rotary coupling

item 10 and barrel item 37.

|

- b) Leakage between hydraulic connector item 34 and flexible

hose item 35 may be cured by use of suitable sealant such

as Loctite.

|

|

Leakage

post seal item 6

|

- This may be due to dirty or damaged seal. To replace

seal item 6 press out pin item 7 and withdraw piston item

5 from gun head item 1

|

- Remove x-ring seal item 6 taking care not to damage bore.

Carefully fit new x-ring seal and ensure that it is properly

seated in groove.

|

- Re-assemble piston item 5 and pin item 7

|

| NOTE: The

longer end or torsion spring item 8 should lie inside lever

item 2.

To

reach a friendly voice, call during our hours of operation:

Monday through Friday, 9 a.m. to 6 p.m. EST

(Eastern Standard Time)

Wood Tech Enterprises

Our website: www.woodtechtooling.com

P.O. Box 2226

Fairview, NC 28730 USA

1-800-TOOLING (866-5464)

Phone: 828-628-4414

Fax: 828-628-4490

Shipping Address:

15 Khristy Scott Lane

Fairview, NC 28730 USA

Copyright © 1998-2008 Wood Tech Enterprises, Inc.

All Rights Reserved. Designated trademarks and brands

are the property of their respective owners. Wood Tech

is not responsible for typographical errors. Prices

are subject to change. All prices are in U.S. Dollars. |